|

|

The Toothpick Bridge

|

A friend of mine asked me to help her son

with the classic math/science project, the

toothpick bridge.

At the time, I remembered

my dad's explanation of a catenary and I

decided to look into that curve as a building

block of the design.

The catenary is curve

made by a hanging chain. A fancy description

would be the 'shape assumed by a rope or chain

of uniform density suspended from two points and

acted upon solely by the forces of gravity.'

The Saint Louis arch is the shape of a catenary.

At that time, we designed and built the bridge, but

in the interest of getting it built, we did not use

the formula for a catenary, I think we simply dangled

a chain ( like the ones the pens are attached to at

the bank) in front of a posterboard and drew the curve.

When my son came home from 8th grade with the same

assignment, I thought I would document our process on

a web page.

A school project, usually assigned in a physics class, or math class for junior high

or high school students, The "Toothpick Bridge" problems tests the reasoning skills

of kids and future engineers.

|

The Toothpick Bridge-Design

|

|

|

|

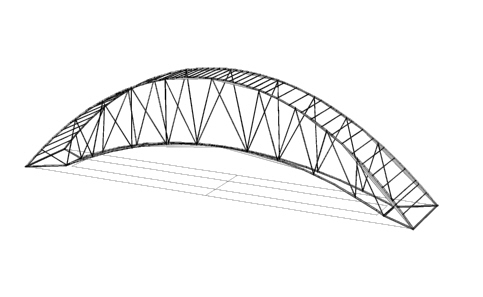

The design relies on the four catenary arches to transfer the weight of

a load to the four feet on each side of the bridge. They work in tandem

like a regular truss with struts that connect the upper arches to the lower

archs. The formula for a catenary arch is y=cosh(x). This 'cosh' function

is the hyperbolic cosine. A sort of obscure trigonometric function used

in non-euclidean geometry. Luckily, it's on many hand-held calcualtors.

A little Algebra...

To normalize the function, we needed to use a particular part of the curve

to get the height we wanted, and then magnify it to the size we wanted.

This involve a little algebra.

Essencially , the lower arch and upper arch

are from the same function for a curve, only the upper arch uses slightly

more of the curve ( to get the proper height ratio) and is therefore less

'magnified'

A little Engineering...

I recently decided to calculate the forces in the struts of a typical

catenary truss. This page will give you a starting point and also an idea

about calculating the tension and compression involved in each member of

your bridge design. The numbers can help you decide which members to reenforce

the most, and how to design the connections with the idea of compression or

tension in mind. Here's the link

A little glue testing...

You know, I really put these pages on my website as an experiment, but since

so many people view the page, I thought I might try to resolve a question that

always arises when defining this problem. What are the strengths of the individual

elements? Well, you have tiny sticks of wood, and white glue.

Well, I needed glue for woodworking anyway, so when I went to Lowes to buy

the glue, I thought,"hey, why not buy several types -- and test them to see which

one is the strongest!".

I was very surprized at the outcome. Something also occurred to me while doing the test. Roughly 400

people visit my site per day, but noone has lifted a finger to help me fund this little

internet adventure. So, anyone who makes a paypal donation to my site will get an email from me

telling which brand performed best and worst in my glue test. It is a non-sanctioned test

I have done of my own accord. The results were surprising and counter to what I expected.

So, without further ado, I give you, the...glue test.

|

The Toothpick Bridge-Construction

|

|

Construction technique is of great importance to success.

|

Start with uniform building blocks

|

|

|

|

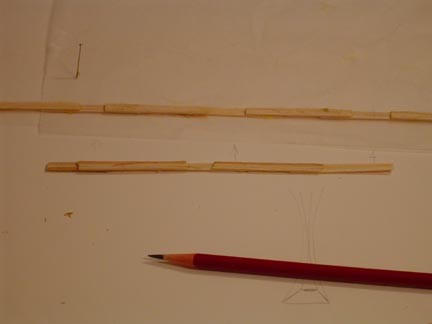

I decided to make easier building blocks by first gluing toothpick 'head to toe', as it

were, and by putting the fat end and the skinny end together, we get a uniform width,

flat, and stronger, building block.

|

|

Start connecting the blocks

|

|

|

Make longer pieces from the building blocks.

|

|

Many Many toothpicks are needed.

|

|

|

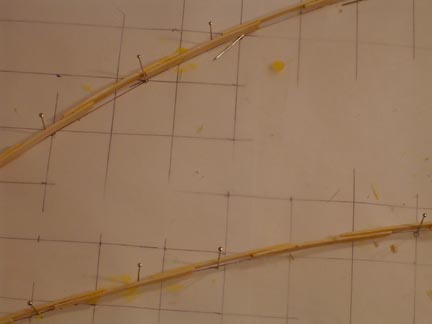

Starting to form a catenary

|

Construct the framework.

| |

|  |

|

Every glue joint is important. Think of each place where building

blocks are glued together as 'rivets' in your bridge. In the most

efficient design, every part of the bridge is acting on the force

of the load. If the bridge is overdesigned, then sloppy workmanship

will suffice. There is a balance between design and safety. With

modern computing and engineering techiniques, some designs actually

fail because they forgot some subtle force, such as wind. The Tachoma

narrows bridge failed when high winds caused it to oscillate. The

footbridge over the Thames was closed when we visited due to a design

fault.

|

Now to assemble the parts.

|

|

|

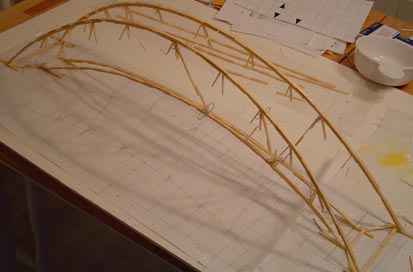

By printing out a grid against the curves we wanted to make,

we drew it to scale and sketched the curves onto several pieces

of printer paper taped together. By laying waxed paper over that

and using pins, we pinned the design and wax paper to a piece of

'foam core' ( get this at an art supply store). More pins can be

used to bend the long straight piece along the desired curve.

|

|

|

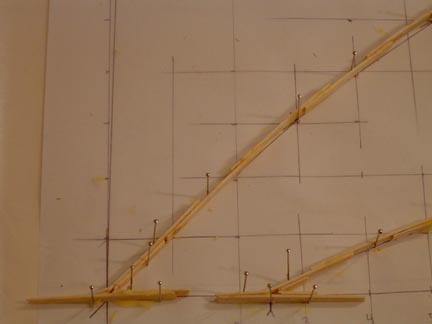

Pinning the arches to the foamcore allows the first connecting

pieces to be added, assembling a 3d framework. The first 'flap'

of the struts between the arches were assembled while still flat.

|

|

|

|

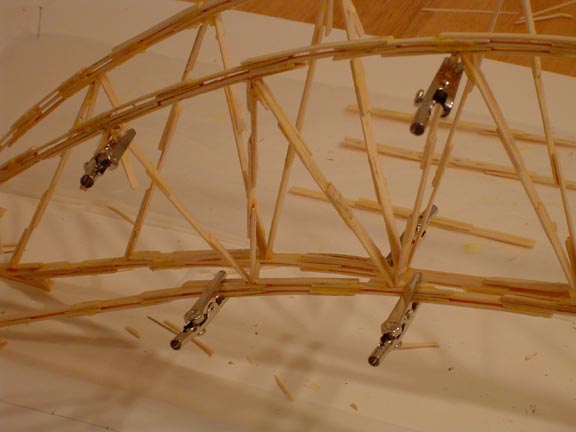

Pins, waxed paper, and now paper clips are a great help to holding

things in place while the glue dries. The glue outside the joint

is just for show, it really doesn't enhance the strength of the

connection. When working with 8th grade level construction crew,

one has to let go.

|

|

|

A trip to RadioShack gets us an amazing ally in the fight for

great glue joints. Alligator clips! They hold the struts to the

flaps and in this design, where the struts are not in the same

plane as the arch, it was a quick way to make the connection.

|

|

|

At this point the bridge still weighs less than 100 grams. The

weight limit for this set of rules was 500 grams. The first bridge

I helped out with actually was disqualified for being too light.

|

|

|

With all the struts, this toothpick bridge weighs 86 grams. To test

its connections, we add weight to it.

one brick,yes -- two bricks, yes, -- three bricks, yes,-- four bricks, hmm, maybe,

maybe not -- five bricks, definitely NOT (yet)

|

|

|

After adding some cross-bracing on the top, the span can finally

withstand the weight of four bricks. We notice that the struts start

to buckle. Our next step will be to beef up the struts.

|

|

|

Well, it's time for the post mortem on our bridge. There are two vastly

different kinds of bricks. One day before the contest, my son told me that

his instructor was planning to use 'paving stones'. We had been testing

with ordinary bricks which weigh roughly 5 pounds each. We 'beefed' it up

to where it could easily withstand the weight of five normal bricks.

Pavers have to weigh about 10 pounds each.

I am disappointed with the methodology of the bridge test. By loading bricks

on top of students work, the instructor misses out on a great teaching

opportunity. What is important to learn is what makes a good design, and

what are the 'weak points' in the design. To find this, one must use finer

methods of testing. For example, a bucket tied 1 inch off the floor from the

span would allow one to learn from the failure and fix it accordingly.

Crushing the work with bricks is entertainment, not unlike a monster truck rally.

The bridge held 3 pavers and then collapsed on the fourth.

The bridges weight was slightly over 1/5 of the maximum weight limit. One thing to

learn is to take advantage of every opportunity the rules allow. Use every

bit of the weight if your goal is to win the competition.

If your goal is to learn the physics of bridge design, don't enter a

competition where 'lamination' into one giant board is allowed -- that is,

unless you love the feel of elmers glue on your fingers.

One very important concept that was apparently lost on my son's classmates

is the ratio of the bridges weight ( unloaded) to the load that the bridge

could withstand before failure. So far I feel sufficiently humbled to have lost

two toothpick bridge competitions for two trusting students. Always too light!!

One note for the future. Luckily I have other children who will benefit from

our knowledge. The next design will be far superior to this one. This bridge

failed because the joints between the arch and struts failed. By orienting the

building block so they are 'flat vertical' the strut connections will be much

easier to make strong.

All in all, I am sure my son learned more with my help, than he might have

without it. I do wish he could have gotten the highest possible score, but

I have found that getting all A+'s is not necessarily the most useful grades

for later in life.

|

A different set of rules arose for a father in Quebec, who was kind

enough to send me his story. See how different this task can by visiting

Round Toothpick story

In searching for the best design, there are a few things to consider.

Since every competition is slightly different, decide what your goal is,

to learn, or to win? I have started a page which will may eventually answer

the question of how best to support heavy weights in toothpick world.

Quest for the best

While you're here, let me know what you think of this page in an

email.

If you would be interested in more detailed instructions

or other designs, let me know that as well. I would like to hear

about the rules for various contests and how the grading and

testing is done. My name is

and just click on it for my email.

|

|

|

|

|Home|

|Pi details|

|About stone|

|The Inventions|

Music Store|

|More Hugh|

|

Lars' Creative Warehouse

Lars' Creative Warehouse

Lars' Creative Warehouse

Lars' Creative Warehouse